|

|

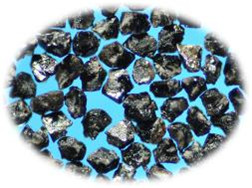

CBN-B10

Features: Black monocrystalline, irregular in shape, low strength, sharp, fragile, and good self-sharpening.

Applications: Widely used in resin bond systems and low-temperature grinding.

|

|

|

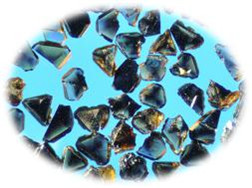

CBN-B15

Characteristics: Black monocrystalline, semi-blocky in form, medium strength, excellent sharpness, balancing grinding efficiency with wheel life.

Applications: Suitable for resin and ceramic bonding systems.

|

|

|

CBN-B30

Features: Black, with regular crystalline structure, high strength, exhibiting unparalleled thermal stability in ultra-high speed and high-temperature grinding.

Applications: Extensively used in ceramic, electroplated, and metal bonding systems.

|

|

|

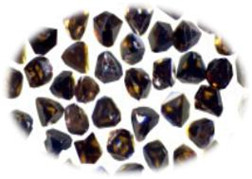

CBN-A20

Characteristics: Amber-colored, irregular in shape with prominent edges, exceptionally brittle, and of moderate strength.

Applications: Frequently used in resin bonding systems.

|

|

|

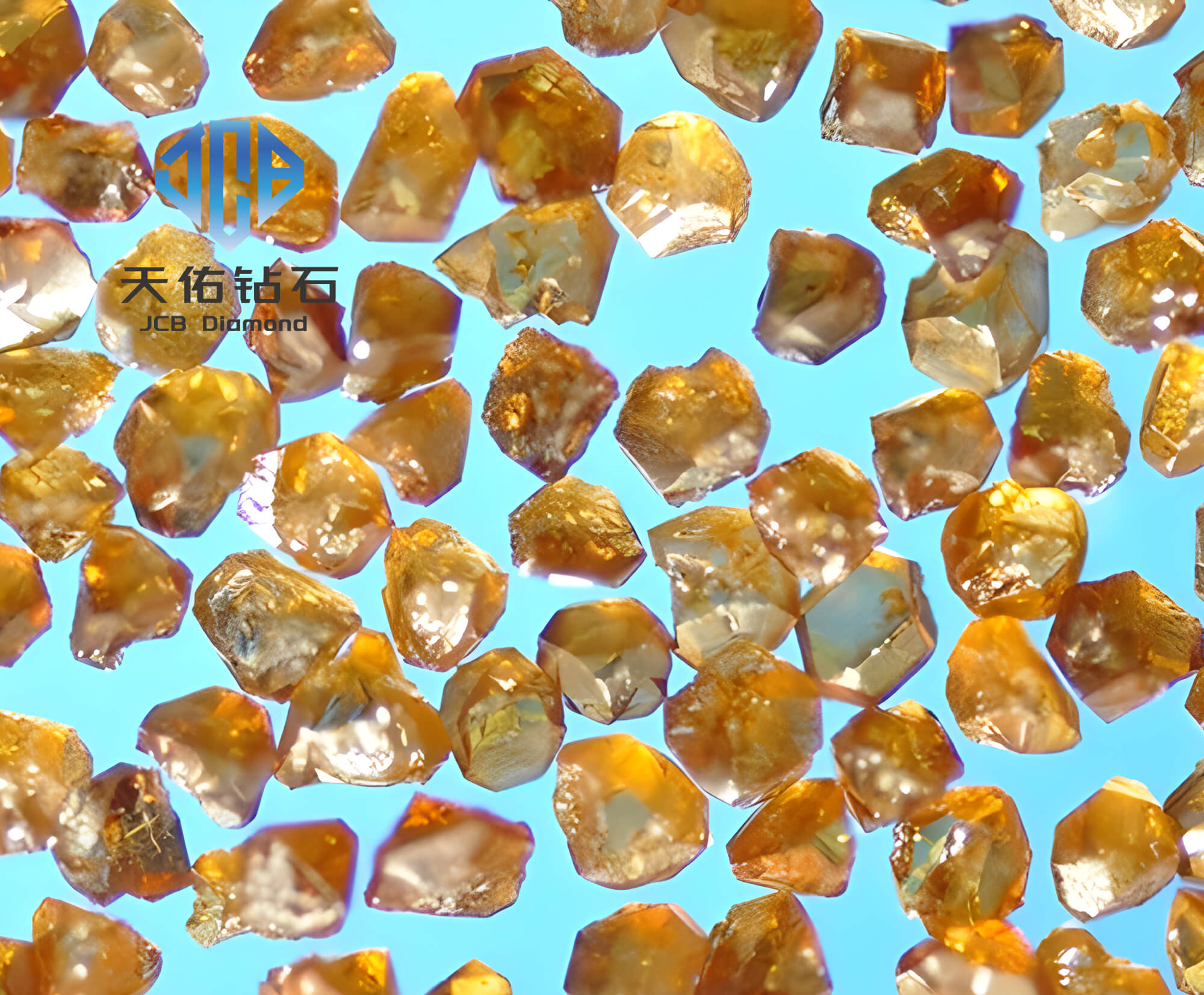

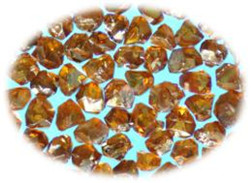

CBN-A25

Features: Amber in color, high transparency, with regular crystalline structure, and higher strength.

Applications: Suitable for ceramic and electroplated bonding agents.

|

|

|

CBN-A40

Characteristics: Dark brown in color, irregular in shape with sharp corners, high strength, and excellent thermal stability.

Applications: Ideally suited for ceramic, electroplated, and metal bonding systems where high performance abrasives are required.

|

|

|

CBN-A45

Characteristics: Deep brown, with intact crystalline structure, high strength, and high thermal stability.

Applications: Compatible with ceramic, electroplated, and metal bonding systems.

|

|

|

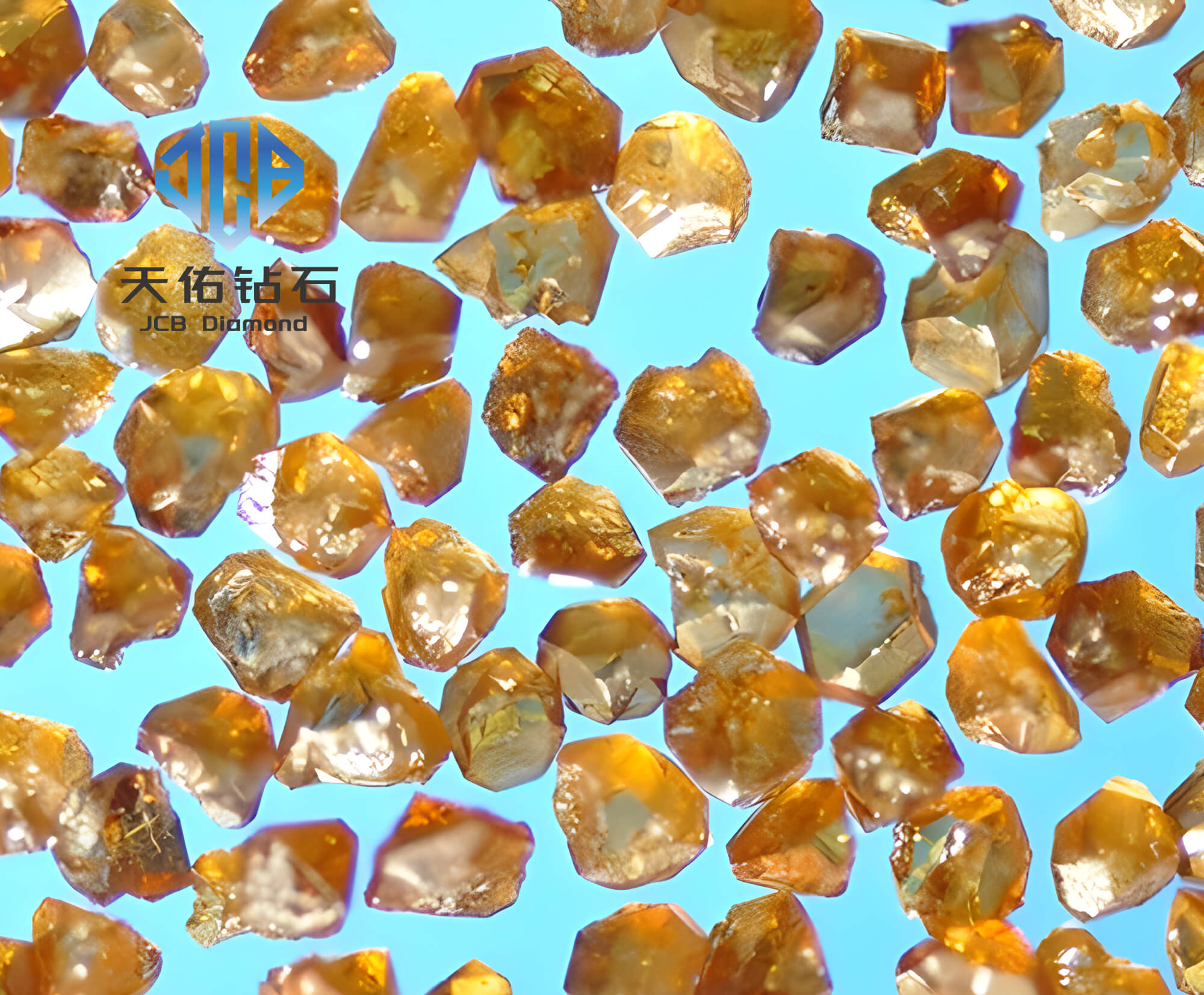

CBN-A50

Characteristics: Golden in color, with regular crystal structure, high strength, and exceptional thermal stability. Demonstrates remarkable grinding efficiency and extended wheel life during the grinding process.

Applications: Well-suited for electroplated and metal bonding systems, particularly for electroplated tooling applications.

|