모형: 2-1

상표: JCB

거친 합성 다이아몬드 - JSD 시리즈

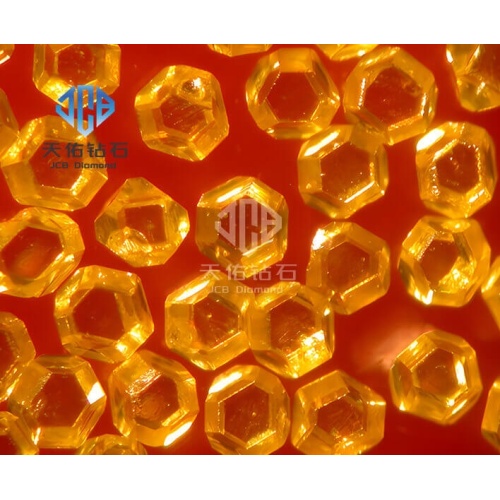

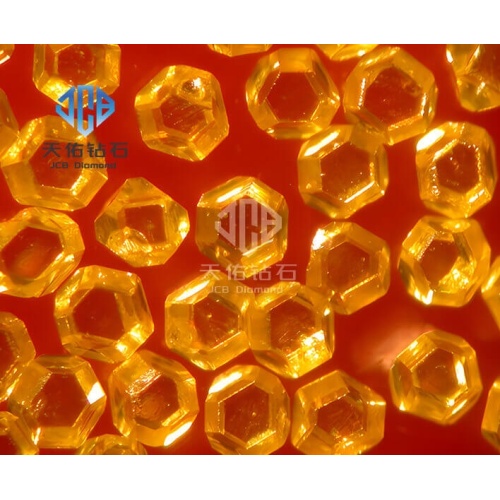

JCB JSD 시리즈 의 거친 합성 다이아몬드는 높은 내구성과 내마모성을 필요로하는 중대 적용을 위해 특별히 설계되었습니다. 20/25 ~ 50/60 범위의 곡물 크기로,이 황금색-노란색 다이아몬드는 완전한 육각형 결정 구조, 낮은 불순물 함량 및 우수한 투명성을 특징으로합니다. 그들의 뛰어난 정적 강도, 충격 인성 및 열 안정성은 산업 공정을 요구하는 데 이상적입니다.

자세히 알아보기 : https://en.jcbdiamond.com/

높은 정적 강도 : 극심한 스트레스와 압력을 견딜 수 있습니다.

충격 강인함 : 충격에 따른 균열 또는 파손에 대한 내성

열 안정성 : 고온 조건에서 성능을 유지합니다

낮은 불순물 함량 : 우수한 선명도와 효율성을 보장합니다

우수한 내마모성 : 힘든 응용 분야에서 긴 서비스 수명을 제공합니다.

다이아몬드 절단 도구 : 돌, 콘크리트 및 세라믹과 같은 단단한 재료 절단, 연삭 및 연마 용

지질 드릴링 도구 : 가혹한 환경에서 고성능 시추 응용 프로그램에 이상적

톱 및 드릴링 장비 : 다이아몬드 톱날, 로프 톱 및 드릴링 도구에 사용

용접 도구 : 높은 열 저항이 필요한 브레이징 및 용접 애플리케이션에 적합

건축 및 광업 : 강화 콘크리트 절단 및 가공에 적합합니다.

JSD 시리즈 거친 합성 다이아몬드는 석재 가공 , 석유 및 가스 탐사 , 건축 및 광업 과 같은 산업에서 널리 사용됩니다. 그들의 강력한 특성은 탁월한 경도, 내마모성 및 열 안정성을 요구하는 응용 분야의 선택이됩니다.

JCB JSD 시리즈 합성 단결정 다이아몬드 거친 곡물은 20/25 ~ 50/60 범위의 입자 크기의 다이아몬드를 나타냅니다. 이들 제품은 황금색-노란색 결정 구조, 6 도구 구조의 완전한 결정 형성, 낮은 불순물 함량, 우수한 투명성 및 뛰어난 정적 강도, 충격 강인성 및 열 안정성을 특징으로한다. JCB JSD 시리즈의 다이아몬드는 주로 다이아몬드 톱날, 다이아몬드 와이어 톱, 얇은 벽 다이아몬드 드릴, 다이아몬드 그라인딩 블록, 다이아몬드 휠, 지질 드릴링 도구 및 브레이징 도구의 제조에 주로 사용됩니다. 석재 가공, 철근 콘크리트 절단, 도로 및 교량 건설, 유리 처리, 석유 및 가스 시추 및 기계 가공과 같은 산업에서 광범위한 응용을 찾습니다.

|

JSD90

Features: Complete and regular hexoctahedral crystal structure, almost no impurities within the crystal, extremely high static strength (Newton), impact toughness (TI), and thermal stability (TTI). Comprehensive performance meets international standards, with excellent wear resistance. Applications: Suitable for cutting tools, drilling tools, and brazing tools under extremely high working intensity conditions, such as cutting and drilling high-strength reinforced concrete, asphalt pavement, and extremely hard granite (F=20), as well as high-performance geological engineering drill bits. |

|

JSD80 Features: Complete and regular hexoctahedral crystal structure, very few impurities within the crystal, high static strength (Newton), impact toughness (TI), and thermal stability (TTI), with excellent wear resistance. Applications: Suitable for cutting tools, drilling tools, brazing tools, and electroplating tools under high working intensity conditions, such as cutting and drilling reinforced concrete, hard granite (F=15), and high-hardness ceramic materials, as well as engineering drill bits. |

|

JSD70 Features: Relatively complete hexoctahedral crystal structure, few impurities within the crystal, relatively high static strength (Newton), impact toughness (TI), and thermal stability (TTI), with good wear resistance. Applications: Suitable for cutting tools, drilling tools, brazing tools, and electroplating tools under relatively high working intensity conditions, such as cutting and drilling concrete, hard granite (F=10), high-grade tiles, and high-hardness refractory materials, as well as heavy-duty grinding tools and medium-to-high-load electroplating brazing tools. |

|

JSD60 Features: Relatively complete hexoctahedral crystal structure, relatively few impurities within the crystal, moderate static strength (Newton), impact toughness (TI), and thermal stability (TTI), with a balance of wear resistance and sharpness. Applications: Suitable for high-speed cutting and drilling under medium working intensity conditions, such as cutting and drilling non-reinforced cement pavement, hard marble, low-hardness granite (F=8), large quantities of building materials, refractory materials, and non-ferrous metal materials, as well as heavy-duty grinding tools and medium-load electroplating brazing tools. |

|

JSD50 Features: Relatively regular hexoctahedral crystal structure, moderate impurities within the crystal, average static strength (Newton), impact toughness (TI), and thermal stability (TTI), with moderate wear resistance and good sharpness. Applications: Suitable for high-speed cutting and drilling under medium-to-low working intensity conditions, such as cutting and drilling soft marble and sandstone (F=6-5), glass, ceramics, and batch building materials, as well as medium-load grinding tools and medium-to-low-load electroplating tools. |

|

JSD40 Features: 90-95% regular crystal structure, moderate impurities within the crystal, relatively low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with average wear resistance and excellent sharpness. Applications: Suitable for high-speed cutting and drilling under low working intensity conditions, such as small-diameter free-cutting drilling tools, as well as medium-to-low-load grinding tools and low-load electroplating tools. |

|

JSD30 Features: 85% regular crystal structure, more impurities within the crystal compared to JSD40, relatively low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with poor wear resistance and excellent sharpness. Applications: Suitable for small-diameter free-cutting tools and drilling tools with excellent sharpness, such as cutting and drilling gemstones, jade, crystal, and other high-brittle materials, as well as small batches of stone, glass, and tiles, as well as medium-to-low-load grinding tools and low-load electroplating tools. |

|

JSD20 Features: 70% regular crystal structure, relatively high impurities within the crystal, rough surface, low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with poor wear resistance and extremely high sharpness. Applications: Suitable for small-diameter free-cutting tools and drilling tools with excellent sharpness, medium-to-high-load ceramic bond tools, low-load metal bond grinding tools, and extremely sharp electroplating tools. Used for processing hard alloys, magnetic materials, glass, tiles, crystal, gemstones, and other brittle materials. Can also be used in combination with high-grade diamonds to adjust tool sharpness. |

|

JSD10 Features: 50% regular crystal structure, high impurities within the crystal, rough surface, very low static strength (Newton), impact toughness (TI), and thermal stability (TTI), with very poor wear resistance, extremely high sharpness, and good self-sharpening properties. Applications: Suitable for medium-to-high-load resin bond tools, medium-to-low-load ceramic bond tools, low-load metal bond grinding tools, and extremely sharp electroplating tools. Used for processing hard alloys, magnetic materials, glass, tiles, crystal, gemstones, and other brittle materials. Can also be used in combination with high-grade diamonds to adjust tool sharpness. |